Being my impatient self, I jumped straight into my next pipe without even thinking about the documentation side of it all… 😅

However. here is number 4! This was a bit of an odd one, and wasn’t actually the pipe that I intended on working on next, but after receiving some new files for Christmas, I wanted to test them out on a cheaper block I had.

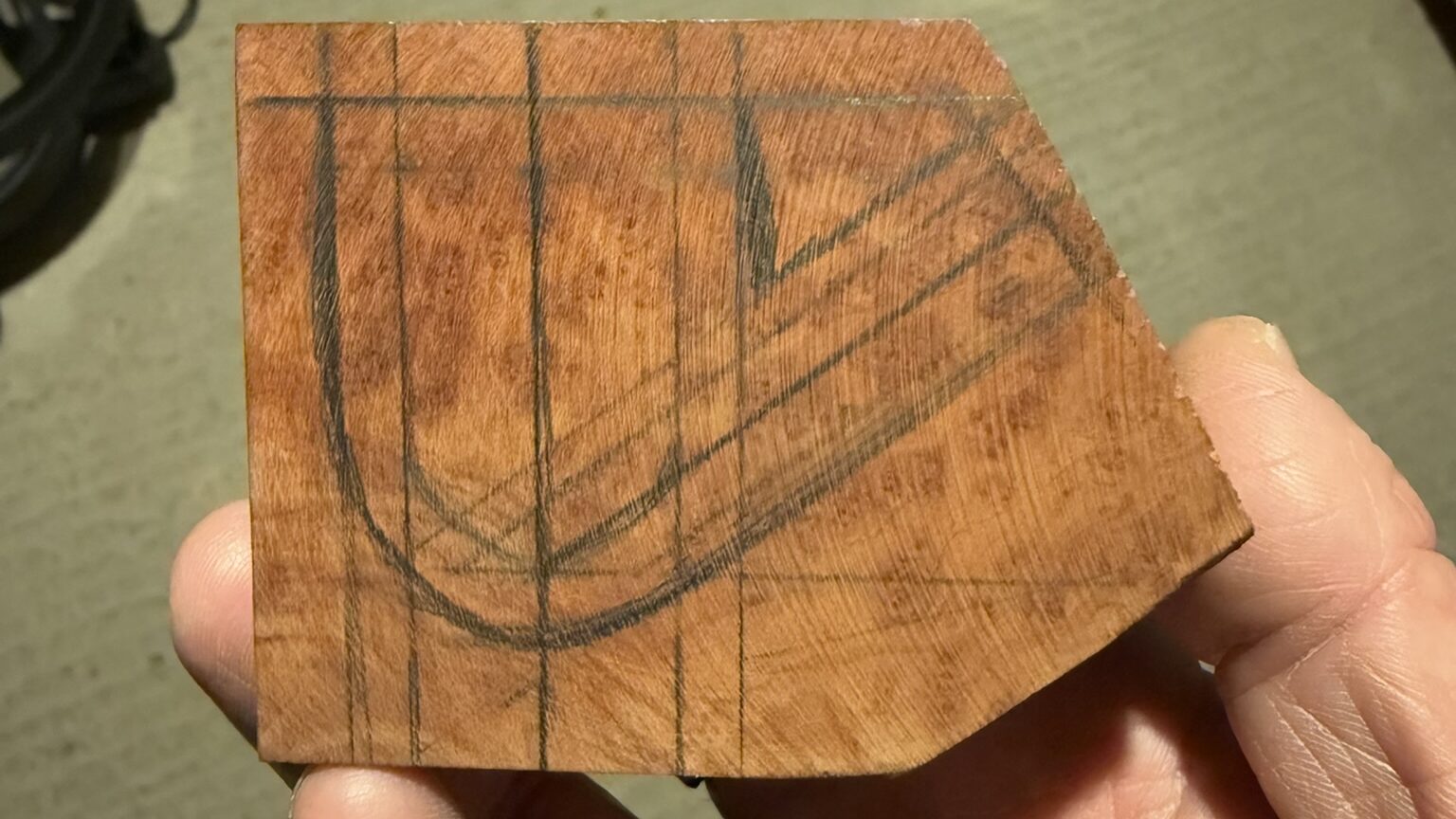

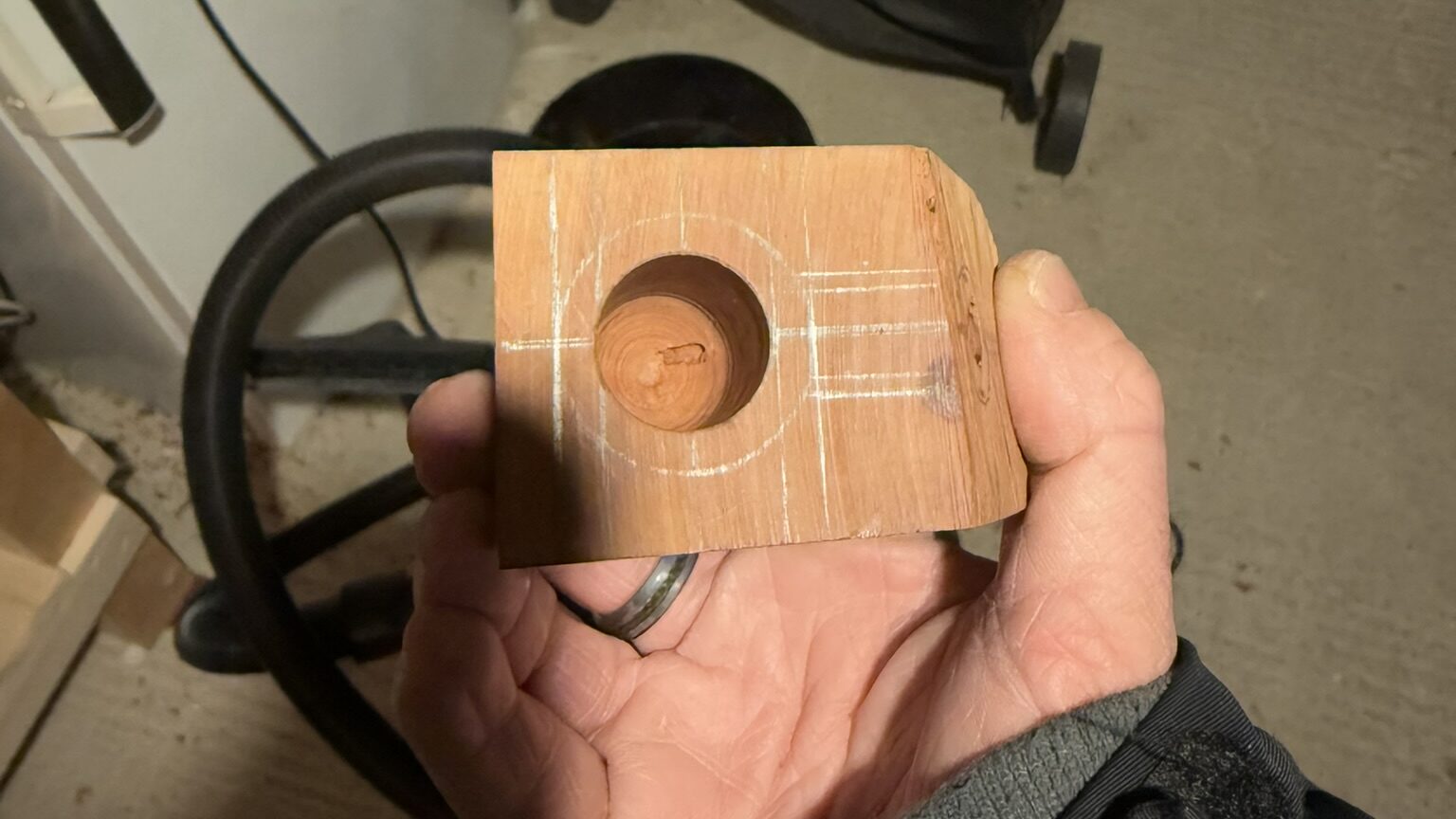

After marking the block up with the pipe shape and lines for drilling, it was over to the press to get the chamber, mortise and airway holes drilled. My airway was pretty off in this stummel which is very annoying, but despite not being happy with this, I figured it was worth finishing it for the practice, plus it might work a nice little shop pipe 😎

In my little box of pre-made stems, I found a couple of ebonite blanks (seemingly pre-formed/moulded stems that need finishing) so I decided to use one of those for the first time for this pipe’s stem.

This stem was also ovular at the tenon end, which is a shape I’ve not worked with before.

I used my french wheel to rough shape the stummel before getting my new files out and using these to start finalising the shape. It’s the first time I’ve used files for shaping and wow are they amazing for this!

After this it was down to finishing it up. I sanded the stummel up to 600 grit before slapping a few coats of black stain on. I sanded the mouthpiece from 180 grit all the way up to 2000 grit. From my reading I don’t think 2000 was probably needed, but I dont have any final finishing compounds to use with my wheel yet so sanded up before using carnauba wax on both the stummel and the mouthpiece to shine them up and get them finished.

Leave a Reply